selected item

ExxonMobil launches Low Carbon Solutions business

CCS is the process of capturing CO2 that would otherwise be released into the atmosphere from industrial activity, and injecting it into deep geologic formations for safe, secure and permanent storage. The United Nations Intergovernmental Panel on Climate Change and the International Energy Agency agree that CCS is one of the most important low-carbon technologies required to achieve societal climate goals at the lowest cost.

ExxonMobil has more than 30 years of experience in CCS technology and was the first company to capture more than 120 million tonnes of CO2, which is equivalent to the emissions of more than 25 million cars for one year.

Plans are advancing for more than 20 new carbon capture and storage (CCS) opportunities around the world to enable large-scale emission reductions. ExxonMobil intends to invest $3 billion on lower emission energy solutions through 2025.

One of these projects is based in Scotland, where through its joint venture in the SEGAL system in north east Scotland, ExxonMobil is progressing discussions to support the Acorn project. This will collect CO2 from the St. Fergus gas processing complex for transport and storage in offshore gas reservoirs.

ExxonMobil Low Carbon Solutions will also leverage ExxonMobil’s significant experience in the production of hydrogen which, when coupled with CCS, is likely to play a critical role in a lower-carbon energy system. Other technology focus areas in ExxonMobil’s low carbon portfolio will be added in the future as they mature to commercialisation.

“With our demonstrated leadership in carbon capture and emissions reduction technologies, ExxonMobil is committed to meeting the demand for affordable energy while reducing emissions and managing the risks of climate change,” said Darren Woods, chairman and chief executive officer.

“We are focused on proprietary projects and commercial partnerships that will have a demonstrably positive impact on our own emissions as well as those from the industrial, power generation and commercial transportation sectors, which together account for 80 percent of global CO2 emissions. We have the expertise that can help bring technologies to market and make a meaningful difference.”

The new projects will complement ExxonMobil’s current carbon capture capacity in the United States, Australia and Qatar, which totals about 9 million tonnes per year, the equivalent of planting 150 million trees every year.

Both companies have been developing plans since 2018 and a final investment decision is expected in mid-2021, with start-up anticipated in 2023. The new plant will convert difficult-to-recycle mixed plastic waste into raw materials that can be transformed into certified circular polymers and other high-value products at ExxonMobil’s petrochemical complex. The project has received financial support from the French government.

Plastic Energy is a global leader in advanced recycling, specialising in recycling end-of-life plastics that would otherwise be destined for landfill, incineration or end up in the environment. It will build, own and operate an advanced recycling plant adjacent to ExxonMobil’s Notre Dame de Gravenchon petrochemical complex in France.

“Our plans with Plastic Energy demonstrate how industry, government and consumers can work together to build a more circular system to capture value from post-use plastic,” said Karen McKee, president of ExxonMobil Chemical Company. “We’re well-positioned to add value through our expertise in plastic manufacturing and high-performance products to help advance projects like this, which deliver sustainable solutions at scale.”

Also in this issue

Take advantage of FREE ExxonMobil gym classes on Zoom

Want to improve your fitness as the lockdown restrictions ease? Then join in the fun and find your motivation with the ExxonMobil Leatherhead Office gym team who are running free online classes for all those with an ExxonMobil email address.

A Postcard from Kazakhstan

Hilary Walsh is a controller and business services manager for ExxonMobil Kazakhstan Inc. Having worked for ExxonMobil for the past 34 years, Hilary took on the assignment in Kazakhstan two years ago. Here, she writes about her experiences…

ExxonMobil Fawley donates £5,000 to carbon monoxide alarm appeal

ExxonMobil Fawley has made a £5,000 donation to a campaign led by the Blue Lamp Trust which will enable hundreds of elderly and vulnerable people across Hampshire and the Isle of Wight to be given carbon monoxide (CO) detectors. Around 60 people in England and Wales die from CO poisoning each year, often due to badly fitted or poorly maintained appliances within the home.

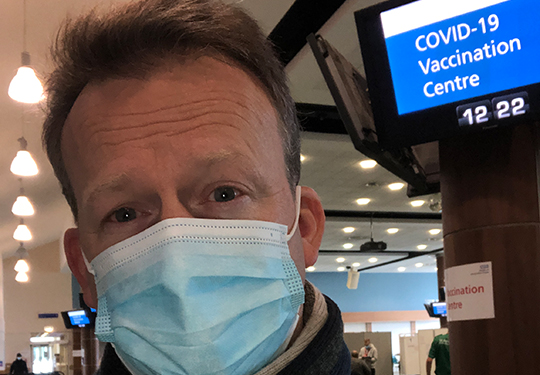

EAME ESG takes strategic approach to the COVID-19 response

One year ago, and almost overnight, COVID-19 changed everything for everyone. For ExxonMobil, ensuring the wellbeing of employees whilst fulfilling its duty to society was a huge challenge. So at the beginning of 2020, in response, the company established several emergency support groups (ESG) including one for the EAME region. Newsline spoke to Rupert Bravery, emergency preparedness & response advisor to discover more…

Huge load travels 700 miles from Moerdijk to Mossmorran

A huge new piece of equipment, which will be installed as part of Fife Ethylene Plant’s £140m investment project has arrived on site.

The 170 tonne, 14 metre by 6 metre Regenerator, is a clever piece of engineering that heats and cools air from the plant’s gas turbine. It arrived during the early hours one Friday morning, after an epic 700-mile journey from the Netherlands, arriving by ship at Burntisland East Dock.